What Happens During a Third-Party Warehouse Rack Inspection?

When a third-party inspector arrives at your facility, their primary focus is to evaluate the structural integrity and safety of your racking system. Here’s what the process typically involves:

1. Structural Integrity Check

The inspector conducts a thorough bay-by-bay examination, looking for signs of damage or wear, such as:

- Deformed structural components

- Bent struts

- Missing studs

2. Product Application Review

Inspectors assess how your racks are being used. Many organizations adopt a one-size-fits-all approach, using existing racks without considering compatibility. Key areas of focus include:

- Load Positioning: Are items improperly placed?

- Weight Capacity: Are racks exceeding their weight limits?

- Beam Deflection: Is there noticeable bending under load?

3. Anchoring Assessment

Inspectors check whether racks are properly anchored to the floor and warehouse structure to ensure stability.

4. In-House Modifications

Any repairs or modifications made by your team are closely examined. Non-standard or unengineered fixes often fall short of industry safety standards.

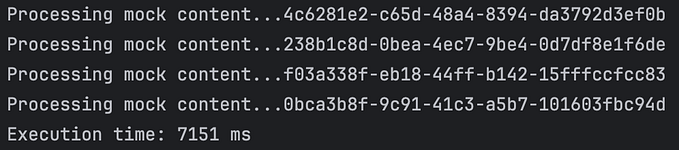

5. Detailed Reporting

Throughout the inspection, inspectors document issues, take photographs, and prepare a comprehensive report. This report outlines infractions, provides evidence, and typically takes about a week to complete.

By the end of the process, you’ll have a clear understanding of your racking system’s condition and recommendations for improvement to ensure safety and compliance.